Blog

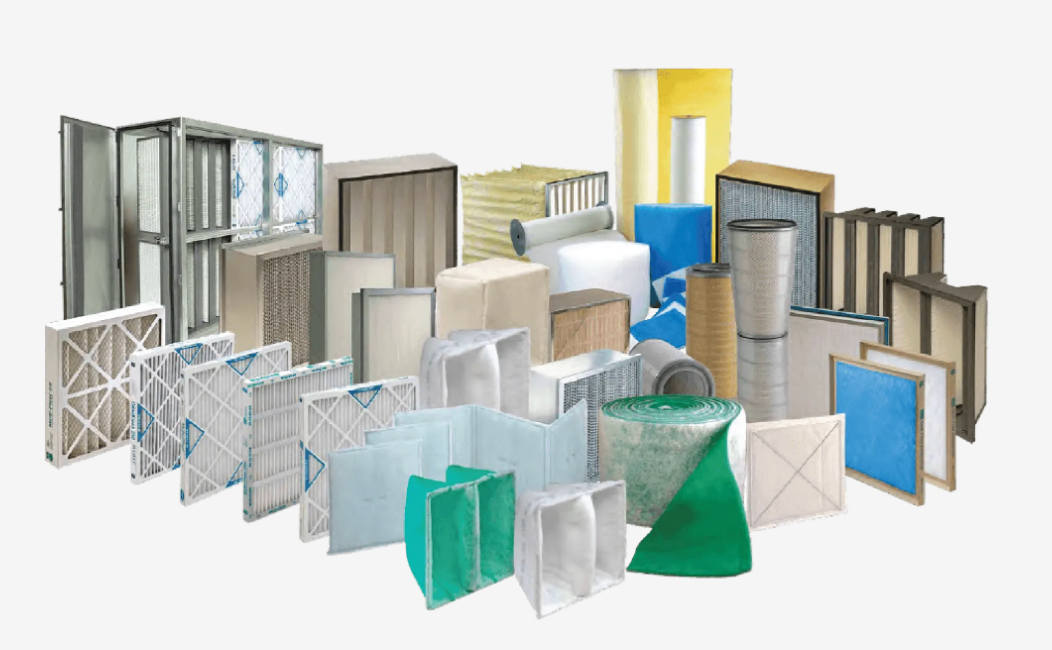

Breathing in clean, pure air is fundamental to our well-being. While inside buildings, we rely on advanced filtration systems to provide clean, quality air. From high efficiency filtration solutions to UV-C systems, today's filtration technology has evolved to meet the diverse needs of various industries. These systems not only provide air purification but also include fluid filters and industrial filters designed for contamination control in sensitive environments. The benefits of using quality advanced filtration systems extend beyond mere environmental protection. They also offer improved air quality, particle removal, and overall better health. Industrial applications particularly benefit from these technologies. When solutions are tailored to specific industry needs, it helps ensure safety and efficiency in operations. As we continue to innovate in this field, clean air solutions are proving to be indispensable across a myriad of settings, showcasing the importance of filtration performance and its impact on everyday life.

When it comes to HVAC maintenance, facility managers and procurement officers often face a tough choice: should they opt for the cheapest air filters or invest in higher-quality options? At first glance, it may seem like an easy decision — after all, a budget filter can cost a fraction of a higher-efficiency model. But what’s not immediately obvious is how cheap filters can actually cost more in the long run. 1. They Need More Frequent Replacements Cheap air filters typically have a lower MERV rating (Minimum Efficiency Reporting Value), meaning they capture fewer particles and clog up faster. The result? You’ll need to replace them more often — sometimes three times as frequently as a higher-quality filter. The labor costs, disposal fees, and bulk purchasing add up quickly. Beyond the direct cost of replacing filters more frequently, there are also logistical and operational expenses to consider. Ordering, storing and disposing of more filters adds administrative overhead, which can translate into higher indirect costs. Facilities that fail to account for these inefficiencies may find their maintenance budgets stretched thin. 2. Increased Energy Consumption When a filter is clogged, your HVAC system has to work harder to pull air through. Studies have shown that using a low-quality filter can increase energy consumption by up to 15%. That added strain on the system doesn’t just drive up utility bills — but it also shortens the lifespan of your HVAC equipment, leading to expensive repairs or premature replacements. Additionally, poor airflow due to a clogged filter means your system must run longer to achieve the same level of heating or cooling. This leads to unnecessary wear and tear on components like blower motors and compressors, which could result in costly emergency repairs and unplanned downtime. Did you know that just 1 mm of dust can reduce coil efficiency by up to 40%? And lower-efficiency (i.e., poor quality) filters allow more dust through, creating dirty coils faster. 3. Poor Indoor Air Quality Leads to Hidden Costs Lower-quality filters allow more dust, allergens and pollutants to circulate in the air, impacting occupant health. In offices, this can lead to lower productivity and increased sick days. In schools, poor air quality has been linked to higher absenteeism. And in industrial settings, dust and particulate buildup can damage machinery and contaminate sensitive processes, leading to costly downtime. Employees or students suffering from poor air quality may experience fatigue, headaches, and respiratory issues, which negatively impact performance and well-being. Over time, this can lead to higher healthcare costs for companies and schools, as well as increased insurance claims due to air-related illnesses. The Cost-Saving Alternative: Smart Filtration Choices Instead of buying the cheapest filters, consider the Total Cost of Ownership (TCO). A high-efficiency filter with a longer lifespan and better air-cleaning capability may cost more upfront but will save thousands in replacement costs, energy efficiency, and equipment maintenance over time. High-MERV filters not only last longer and perform better but also improve HVAC efficiency, reducing long-term energy consumption. By working with an air filtration specialist, facility managers can determine the optimal balance between cost, efficiency and longevity — leading to substantial savings over time. If you have questions about your air and water filtration challenges — whether it’s finding customized air filter solutions, faster delivery, or more cost-effective options — please call (423)-775-2932 or email us .